Labassa Entry Door Sidelight Conservation

In 2019 the National Trust was awarded a DELWP Living Heritage Grant to undertake conservation works to its State listed properties over two years. This year, part of this grant has been used for conservation work to one of the sidelights at Labassa front door.

Powder at the base of these windows had being noted, suspected to be lead oxide caused by a break-down of the lead. Plate glass had being fitted as a protective system previously and it was suspected that this was contributing to a build-up of moisture. Stained Glass artist and conservator Bruce Hutton of Almond Glassworks was brought in to assess the sidelights and see what work was needed to conserve them. Bruce states that “there is much debate about the double glazing of leadlight, principally, whether it needs to be ventilated to prevent condensation. The detrimental presence of moisture in such an environment has been well documented for medieval glass, however the effect upon glass produced post 1850 is not so studied”.

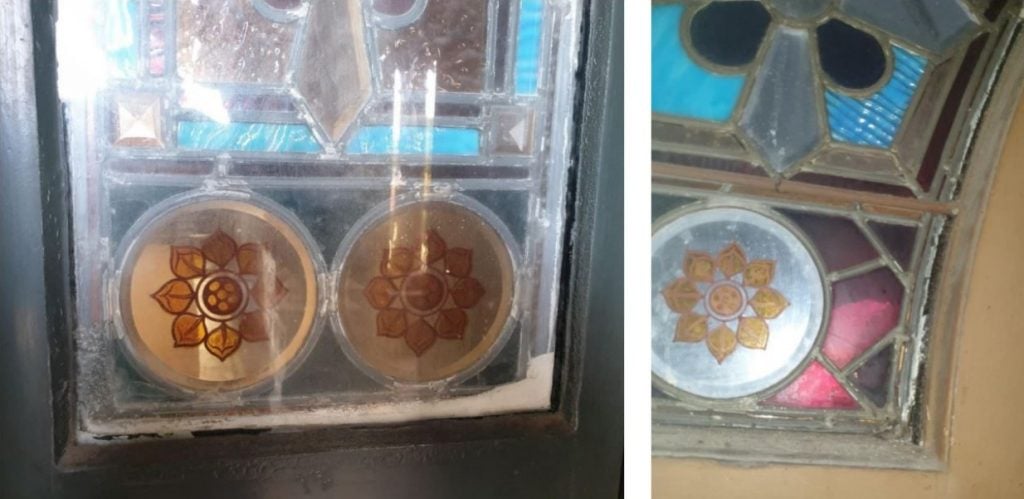

Left: shows the sidelight prior to removal. The powder at the base of the window is most likely lead oxide from the calmes.

Right: shows both the steel reinforcing bars and the gap filled with black putty between the leadlight edge and the frame.

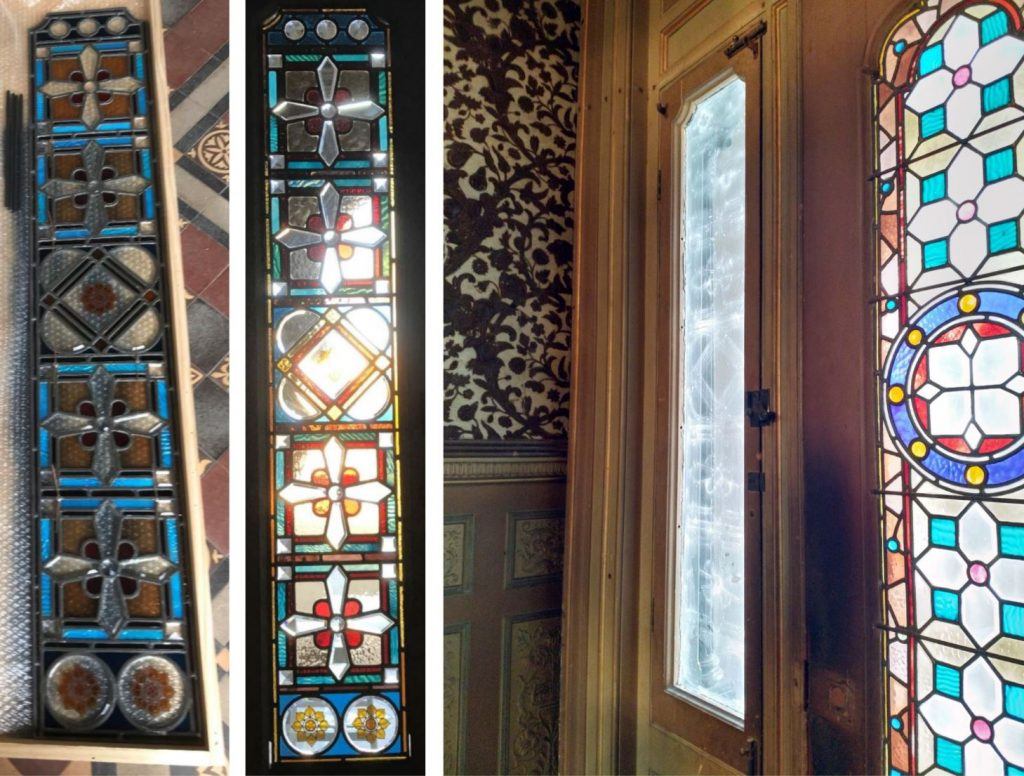

In order to clean the trapped grime, it was decided that the leadlight was the easier of the two layers to be removed and refitted. There was insufficient information about the external plate glass and whether it was contemporary to the lead lighting or at least 19th century. The panel also needed some attention to the lead itself to slow the obvious oxidisation. The perimeter lead was renewed, a patina applied to all the calmes to reduce the lead being exposed to air and the surface was treated. New copper bands were fitted to the window and the steel reinforcing bars treated for rust and painted.

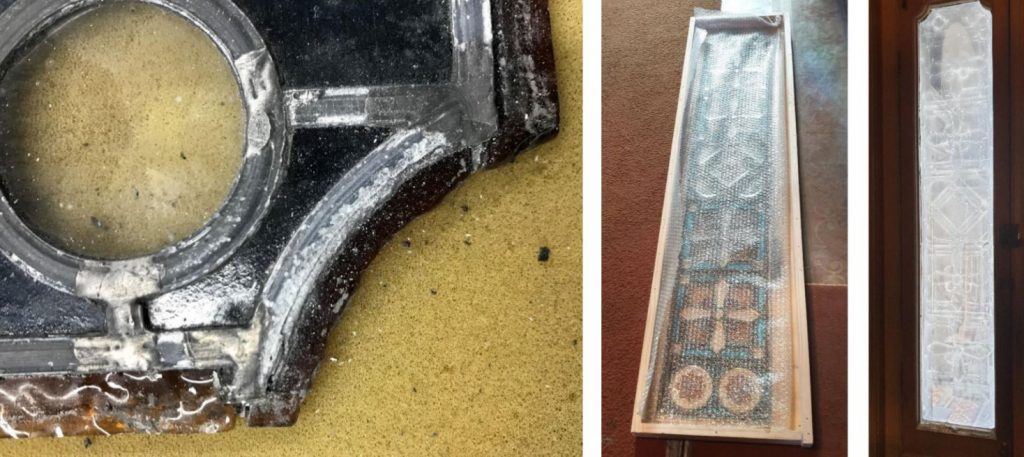

Left: This is a detail of a corner section of the panel. The white powdery areas show the lead in the process of degrading through oxidisation.

Middle: Window being packed

Right: Residual lead oxide on the external glass.

The glass was now clean, packed, and ready to be fitted back in the previous manner. The only slight change was an area at the top of the panel and two small areas at the base that were left devoid of putty. The hope is to introduce some form of ventilation to the interspace. Now that the system is understood, it is not too difficult to remove the panel and revisit, if the internal environment causes the lead to degrade.

Work completed thanks to a DEWLP (Department of Environment, Water, Land and Planning) Living Heritage Grant and Almond Glassworks.